Our own Miniature Ballscrews – General Information

Ballscrew dynamics and positioning accuracy primarily depend on the accuracy of production and the technical implementation of the specified tolerances.

Our standard Miniature Ballscrews are all designed and made in the UK under AS9100 Rev D and/or ISO 9001:2015 and are supplied using Carbon Steel material hardened to 60 ±2 HRC. We can also manufacture in Stainless Steel where corrosion resistance is vital.

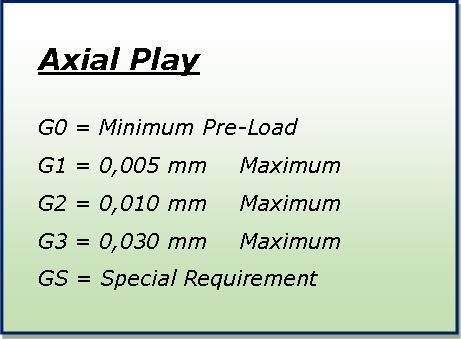

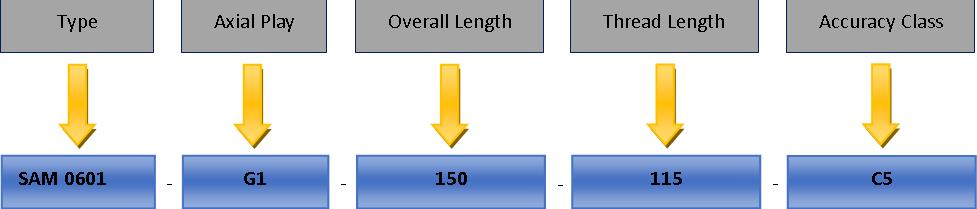

PGM Reball Part Numbering System

Thread Profile

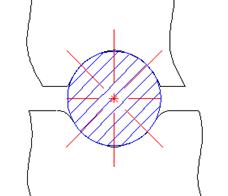

Our miniature ballscrews have “Gothic Arch” thread profiles and with the optimal relationship of ball diameter to track radius this thread profile generates a contact angle between shaft and nut of around 45°.

This gives our ballscrews very favourable running characteristics at maximum axial loads. The ball track profiles for all our miniature ballscrews are ground after heat treatment using the most advanced machines.

Pre-loading

Our miniature ballscrews have “Gothic Arch” thread profiles and with the optimal relationship of ball diameter to track radius this thread profile generates a contact angle between shaft and nut of around 45°.

This gives our ballscrews very favourable running characteristics at maximum axial loads. The ball track profiles for all our miniature ballscrews are ground after heat treatment using the most advanced machines.

Tolerance Class

Our Ballscrews are manufactured to tolerance Class 3, 5 & 7 according to DIN 69051